To all those Functional Safety Engineers, who are immersed too deep inside the ISO26262, buckle your seat belts! Let us take a tour outside the 26262!!

The ISO26262 primarily focuses on “System” Safety. However, the overall Safety in the context of car is far beyond just system safety. It is about measures and features that are designed to minimize the risk of accidents, protect vehicle occupants, and reduce the severity of injuries in the event of a hazardous situation. It covers various aspects of vehicle design, technology, driver assistance systems and even environmental aspects that are aimed at both preventing accidents as well as to minimize injuries and harm in the event of an accident.

Automakers and regulatory bodies have taken continuous efforts to improve Safety standards, implement newer technologies and develop safer designs, and hence several standards have also been introduced. We can broadly group these standards into the following buckets:

- System Safety (which includes component safety)

- Technology Safety

- Vehicle Safety (which covers regulations and safety ratings)

- Manufacturing Safety

In this article, we aim to give you a peek of the vast breadth and depth of Automotive Safety. Please note that this is not intended to be a comprehensive guide of all the standards and regulations related to Safety (so don’t quote us on that!!).

Now, let us deep dive into each of these buckets.

System Safety

This is probably the one most of us are familiar it. This is the area that ISO26262 and SOTIF primarily focus on. The Electronic Components that are used in a System also have specific standards such as AEC-Q which indirectly promote road safety.

Figure2: System Safety

Standards

ISO26262 and SOTIF

ISO 26262 and SOTIF (Safety of the Intended Functionality) are both standards that contribute to system safety in the automotive industry, but they address different aspects and have interrelated elements. While ISO 26262 focuses on functional safety in the development of electrical and electronic systems, SOTIF complements ISO 26262 by addressing hazards arising from limitations in the system's intended functionality, even if the system is functioning as designed. SOTIF focusses on sensor errors, environmental conditions, misuse of system and other complex scenarios that challenge the system's capabilities.

AECQ

The AEC-Q standards, developed by the Automotive Electronics Council (AEC) primarily focuses on the reliability and performance requirements for electronic components used in automotive applications. These standards do not directly address road safety aspects, but they indirectly contribute to it by reducing the likelihood of component failures that could lead to accidents. It covers these Key aspects:

- Improved Automotive Component Reliability: The AEC-Q standards ensure that electronic components used in vehicles meet stringent reliability requirements. Reliable components help maintain the proper functioning of critical safety systems, such as braking, steering, and airbag systems.

- Quality Management System: The AEC-Q standards emphasize on robust quality management systems by automotive component manufacturers. These systems promote consistent and controlled manufacturing processes, leading to more reliable and higher-quality components.

- Endurance and Environmental Testing: AEC-Q standards require components to undergo rigorous testing, including environmental stress testing and extended operational life testing. These tests ensure that components can withstand the harsh conditions and long lifespans typical in automotive applications. Components that pass such tests are less likely to malfunction.

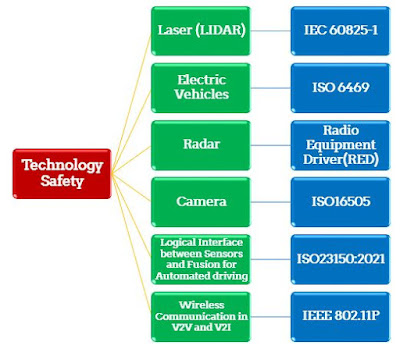

Technology Safety

In the automotive industry, some standards are used for specific technologies to ensure their performance and reliability. While they don’t directly cover the topic of Safety, these technologies are areas where performance and safety overlap in their goals. Compliance with these standards for sensors and EVs helps facilitate the development, integration, and deployment of advanced driver assistance systems and autonomous driving technologies. Here are examples of some of the technology specific standards.

Figure3: Technology Safety

Standards

Let us go deeper into couple of examples:

Camera Sensors

ISO 16505: This standard specifies the performance requirements and test procedures for camera-based Advanced Driver Assistance Systems (ADAS) and provides guidelines for the design and performance of camera monitor systems.

While ISO 16505 focuses on the technical aspects of camera monitor systems, it indirectly contributes to safety by promoting clear and reliable visibility, which can assist drivers in avoiding collisions, detecting pedestrians or obstacles, and making informed decisions while driving the vehicle.

LIDAR Sensors

LIDAR Sensors use eye-safe laser beams to create a 3D representation of the surveyed environment. LIDAR Sensors must meet the FDA eye-safety standards under

IEC 60825. IEC 6082-1 is an international standard used for requirements and guidance for the safety of laser products. It specifies the classification of lasers, labelling requirements, and safety measures to protect users and operators from laser radiation hazards, which can typically lead to eye and skin hazards.

Vehicle Safety

There are several regulations and standards globally that focus on vehicle safety such as United Nations Regulations, Federal Motor Vehicle Safety Standards (FMVSS), European Union Vehicle Safety Standards, ADR Standards, IIHS (Insurance Institute for Highway Safety), Japan Automobile Research Institute (JARI), Automotive Research Association of India (ARAI) etc. These standards cover the following broad areas:

- Active Safety

- Passive Safety

- Environment Safety

- General Safety

Figure4: Vehicle Safety

Standards

Let us look at some examples of the numerous regulations and standards worldwide that address vehicle safety.

United Nations Regulations

The United Nations Economic Commission for Europe (UNECE) develops and administers a series of regulations known as UN Regulations. These regulations cover various aspects of vehicle safety, including crashworthiness, occupant protection, passive and active safety systems, and protection of environment.

Some notable UN Regulations include UN R14 (Safety-Belts), UN R141 (Tire Pressure Monitoring), UN R121 (Location and Identification of telltales and indicators), UN R129 (Child Restraint Systems), and UN R140 (Electronic Stability Control).

Federal Motor Vehicle Safety Standards (FMVSS)

In the United States, the National Highway Traffic Safety Administration (NHTSA) establishes Federal Motor Vehicle Safety Standards (FMVSS) that regulates vehicle safety. Like UNECE, FMVSS covers a wide range of safety aspects, such as occupant protection, crashworthiness, lighting, tires, braking systems, head restraints and more.

The NHTSA has made significant contributions to car safety by setting standards, conducting rigorous crash tests, promoting the use of safety equipment such as AEB, Seat belts, Airbags etc, encouraging technological advancements and investigating vehicle defects and safety-related issues leading to recalls and prompt actions against Manufacturers.

Examples of FMVSS include FMVSS 208 (Occupant Crash Protection), FMVSS 206 (Door Locks and Door Retention), FMVSS 305 (Electric-powered Vehicles), and FMVSS 111 (Rear View Mirrors).

European Union Vehicle Safety Standards

The European Union (EU) sets vehicle safety standards through various directives and regulations, like the above-mentioned standards. Besides pushing manufacturers to adopt safety innovations and improve vehicle safety performance, it has also promoted harmonization of safety standards across member states, ensuring consistent safety requirements for vehicles sold throughout the EU.

NCAP Programs

New Car Assessment Programs (NCAP) are voluntary programs that assess and rate the safety performance of vehicles based on standardized crash tests and safety equipment evaluations. The Safety ratings given by the NCAP programs provide consumers with valuable information to make informed decisions about vehicle safety. The Global NCAP consolidates the NCAPs for the various regions. The Global NCAP takes regular initiatives to improve the regulatory requirements. For e.g., thanks to the NCAPs, the Indian Government had made ESC mandatory in 2022.

Examples include Euro NCAP (Europe), NHTSA NCAP (United States), ANCAP (Australia), and JNCAP (Japan).

However, here’s the irony; In 2002, in the U.S. the pedestrian and motorcycles and bicycles were up 13%, even though nearly all new cars rated by U.S. NCAP received a 4- or 5-star safety rating. The NCAP calls this phenomenon “Starflation”. But could this the “Safety Paradox”? Are human drivers taking more risks once the cars are made safer? or is the bar set too low to receive a 4- or 5- star rating?

The Global NCAP have stepped up to investigate this and to see why these star ratings don’t work and how to improve the situation.

Manufacturing Safety

Figure5: Manufacturing Safety

Standards

The IATF 16949 used in the Manufacturing Industry is one standard that is similar to AECQ, in the sense that it does not directly focus on Safety but indirectly contribute to Safety.

ISO/TS 16949 was originally created in 1999 as a globally recognized quality management system (QMS) standard for the automotive industry. It aimed to harmonize and streamline automotive QMS requirements across the global automotive industry, including manufacturers, suppliers, and other stakeholders. This standard incorporates the ISO 9001 requirements with the addition of specific automotive industry-related requirements. In 2016, the ISO/TS 16949 was cancelled and replaced by IATF 16949. This certification is commonly required by automotive manufacturers as a prerequisite for becoming an approved supplier.

Although IATF 16949 primarily focuses on quality management, it indirectly promotes safety by ensuring that organizations in the automotive industry have effective processes and controls in place to prevent product failures, defects, and non-conformities. This includes aspects related to the design and development of products, production and manufacturing processes, and risk management.

Summary

How do organizations ensure that all the standards and regulations that are relevant to their products and technology areas are satisfied? In our opinion, there are two ways this could be done:

- The “process” requirements from the corresponding standard must be integrated in the Organization’s Internal design and development process. For example, standards like AECQ, IATF16949, ISO26262 or SOTIF have requirements on what process or methods should be followed. These should be integrated as part of the regular process followed by that Organization.

- “Technical” requirements stated in these standards must be brought in upfront as a requirement for the corresponding skill area. For e.g., if there is a regulatory requirement relating to the position of Camera, that needs to be brought in as a requirement to the Mechanical team at the start of the program.

Going forward, We think Companies should start thinking of “Product Safety” teams as part of their Organizational Structure; i.e., to have dedicated teams to drive the adherence of all the Product Safety Standards and Regulations in the Organization. Let us know your thoughts about this!

Comments

Post a Comment